An energy recovery project in Arthur and Toni Rembe Rock Hall at Mission Bay will soon be making significant strides toward campus-wide sustainability goals. For the project, Facilities Services and Real Estate are partnering to install a heat recovery chiller at Rock Hall, which will simultaneously produce 45°F chilled water and 140°F hot water. The project will reduce reliance on natural gas and implement zero-carbon heating solutions.

“This system will provide approximately 83% of heating needs for the Rock Hall research building —offsetting traditional heating sources and reducing emissions,” said Real Estate Project Manager Eric Rodan, who is leading the project delivery on the Campus Design & Construction (CD&C) team.

The reclaimed heat will:

- Prevent approximately 865 metric tons of carbon dioxide (CO₂) emissions annually — about 7% of Mission Bay’s total carbon footprint.

- Reduce the load on the utility plant’s cooling system by over 20%, saving an estimated 1.5 million gallons of water per year.

UCSF’s early success with this technology at the Bayfront Medical Building and Peninsula Outpatient Center is helping to pave the way for broader implementation across its campuses. Heat recovery chillers are being integrated into more new building projects to support long-term decarbonization efforts. These include the UCSF Health Helen Diller Hospital and the Barbara and Gerson Bakar Research and Academic Building, both under construction at Parnassus Heights. In addition, the New Hospital Building at UCSF Benioff Children’s Hospital Oakland is being designed with the same concept, using heat removed by the air conditioning system rather than rejecting it to the atmosphere.

How Does a Recovery Chiller Work?

“UCSF’s lab buildings are unique,” said Eric. “Zones such as data centers and MRI rooms may require cooling while, at the same time, lobbies, offices, and restrooms may require heating.”

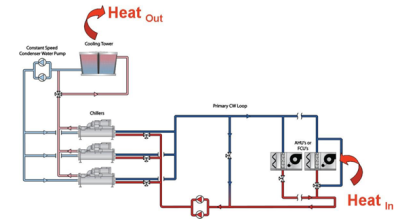

The Mission Bay campus uses a district heating and cooling system with insulated underground pipelines. While cooling is needed year-round in research and medical buildings, traditional systems discard that excess heat. This project ensures that energy is captured and reused efficiently, aligning with UCSF’s climate action goals.

In standard chillers, excess heat generated from cooling — like what is needed for data centers — is expelled into the atmosphere. Heat recovery chillers, however, capture most of that energy and repurpose it for heating other parts of the building.

While heat recovery chillers operate similarly to standard chillers, the key difference is that instead of rejecting all heat through cooling towers, they redirect it to areas where heat is needed.

Collaborative Efforts for Sustainability

The success of the Rock Hall Heat Recovery Chiller project depends on strong collaboration among cross-functional teams. Key partners include UCSF Real Estate, multiple Facilities Services teams, the Office of Sustainability, and external partners, including the design firm Arup Group Limited (ARUP Engineering) and Point Energy Inc. for the conceptual study and peer review. The project is scheduled to begin within six to 12 months, with an anticipated completion in October 2026.

Benjamin Levie, Campus Energy Manager on the Facilities Services Engineering and Utilities Services team, emphasized the year-round benefits. “It will provide free hot water for heating in cooler months and provide cooling to six lab buildings on the district energy loop. The recovery of heat and reuse also means that a cooling tower doesn’t need to be run, saving additional energy and water for many months of the year.”

Kira Stoll, UCSF Chief Sustainability Officer and Executive Director of the Office of Sustainability, said the effort aligns with UCSF’s broader goals to reduce carbon emissions, conserve water, and advance inclusive environmental stewardship. “I am excited about the savings that will come from the energy recovery project at Rock Hall. It helps to create a more energy-resilient campus and highlights our commitment to reducing fossil fuel use.”